As technology advances, companies often look to create materials that can be reused or at the least, recycled. Medical Devices are an industry that creates a large amount of waste. In response to this “medical technology company BD (Becton, Dickinson and Company), and Casella Waste Systems, a solid waste, recycling and resource management services company, today (October 16, 2023) announced the result of a recycling pilot to manage discarded syringes and needles. The pilot led to 40,000 pounds of medical waste being recycled and diverted from disposal.”

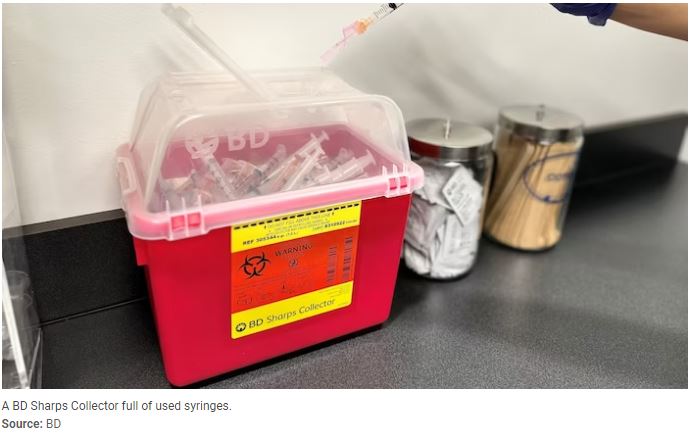

Healthcare facilities continue to contribute to the largest quantities of medical waste (to be expected), specifically syringes, which until now, have been difficult to recycle due to the need for safe handling and sterilization before they can be put into the recycling process. This pilot is the “first large-scale effort” to understand the possibility of recycling medical waste. The hope is that it could open the doors to recycling more medical waste materials.

How does this recycling pilot and potential program impact labeling? These items are reallocated through the manufacturing process, and properly labeled. Based on their intended use, the labeling may need to include identification that signifies it has been “rebuilt or reconditioned”.

These recycled products will need to be differentiated from other products in warehouses so having an integrated ERP system that can ensure accurate inventory controls and compliance measures is vital. Pragmatyxs can help implement and support a labeling solution that can achieve accuracy and efficiency while helping manufacturers reduce medical waste and manufacturing costs.