Product labeling and identification are of paramount importance to global manufacturers and distributors. Fast and accurate labeling is essential in meeting customer and regulatory requirements and ensuring the right product is being shipped — on-time.

Despite these needs the present state of “enterprise” product labeling often consists of a hodgepodge of homegrown or obsolete standalone applications that do not support current standards; are difficult to maintain and limit the company’s ability to respond to rapidly changing demands.

As an essential component in the production process, labeling systems warrant an approach that yields utility-like reliability, scaleability and flexibility. A true enterprise labeling system must:

- Produce accurate and legible label output

- Provide high availability to support around-the-clock, global manufacturing and distribution activities

- Consistently operate at performance levels adequate to support normal and peak production workloads

- Quickly adapt to changing production and labeling requirements

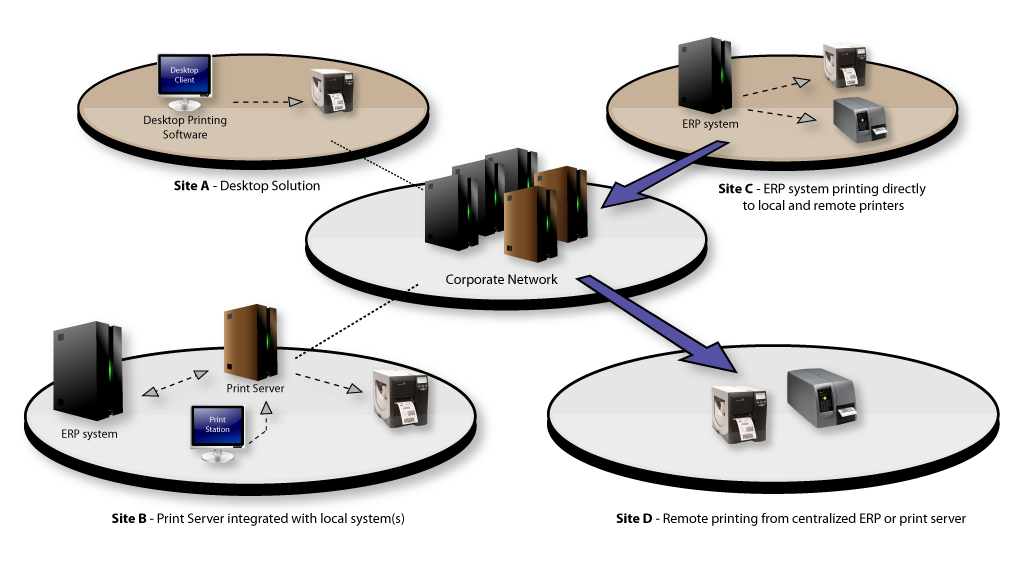

Despite these demands it is not uncommon for large organizations to have separate and often different labeling applications operating at each of their facilities. Decisions on software purchases and labeling standards are made locally and it isn’t until new mandates or worse, a compliance issue occurs, that one-off local solutions have a company-wide impact. This approach often results in:

- Increased cost to transfer the manufacture or distribution of goods between sites as label content and design has to be created in the standalone system

- The inability to adopt current or emerging product labeling standards such as two-dimensional bar codes and RFID

- Production delays and downtime due to poor performing and unreliable legacy software and hardware

Ultimately, the common approach to enterprise labeling is overly complex; difficult to support and lacks robustness and flexibility.

The Service Approach

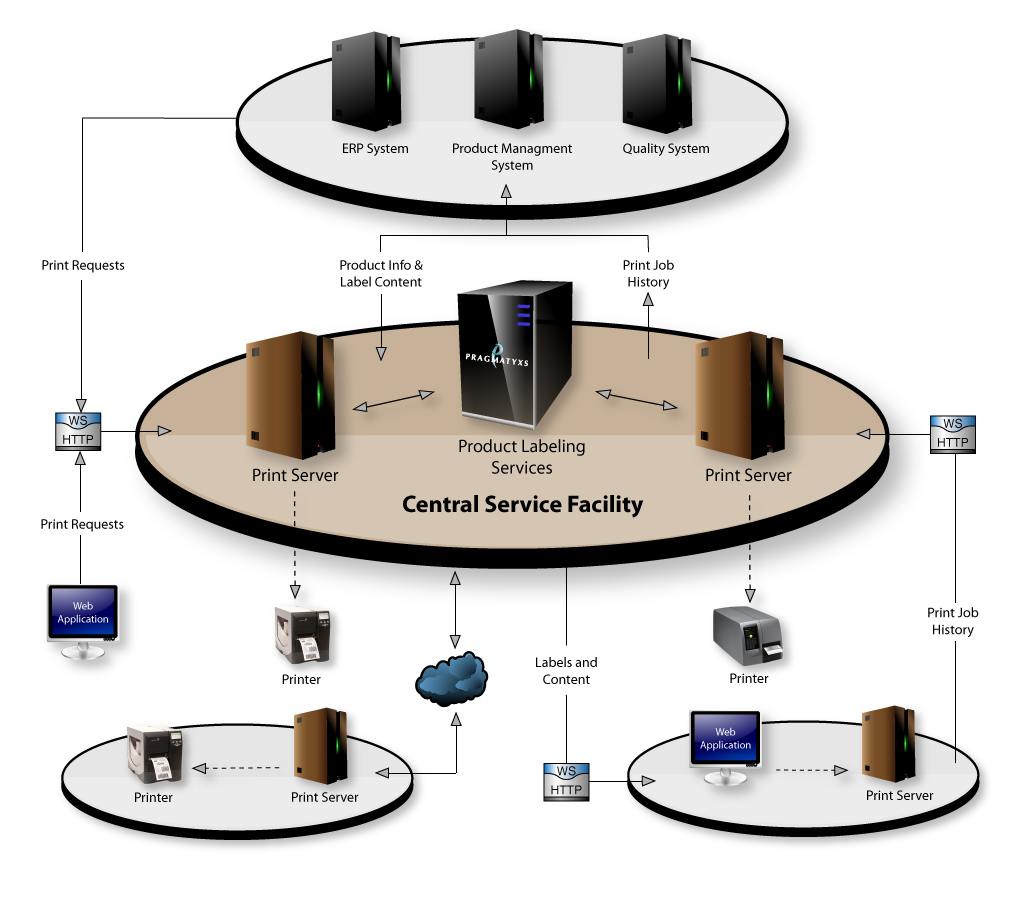

A service or utility approach to architecting and deploying product labeling systems can provide a more unified, scaleable and reliable approach. Services can be designed to automatically accommodate changing production demand and provide failover in the event of a system outage. Labeling services are accessible from any location within the enterprise and securely support external partners and facilities.

A variety of interface options are provided for the labeling service including direct printing from on-premise commercial enterprise applications; custom internal web applications and hosted solutions. Additional services include label design and content approval; print history inquiry and job status monitoring — all capable of distributed deployment with centralized management.

Labeling as a Service is presently not an out-of-the-box product but rather a concept for delivering mission critical product labeling systems. It is an approach that software vendors, solution integrators and businesses should consider for both new deployments and retrofitting environments where business needs are not being met and support costs and service interruptions are high.

It is best to prioritize your labeling needs and focus efforts on services that address your most urgent needs. An evolutionary approach that values thoughtful design, thorough testing and continuous refinement will help avoid the myriad of poorly implemented systems you are dealing with today!