We all have the excitement of those brown boxes waiting on our doorstep and the sheer joy of finding out what’s inside. Now follow that box through the steps it took to get to you and add in all the points in which something could go wrong, and it is quite impressive that it made it to its expected destination. “Barcodes ensure traceability throughout supply chains as parcels travel on high-speed conveyors, but poorly printed labels, damaged barcodes, low contrast, and colored backgrounds are difficult or impossible to read for scanners.”

Barcodes are used in a multitude of industries from manufacturing, logistics, and transportation to pharmaceuticals, aerospace, and food/beverage. They are used to not only track the movement of products, but the materials used to make them. Accuracy for scanning is always an issue, averaging a read rate between 94% – 96%. This means that 4% – 6% of barcodes have an error and require manual processing to fix them which can tap into valuable resources.

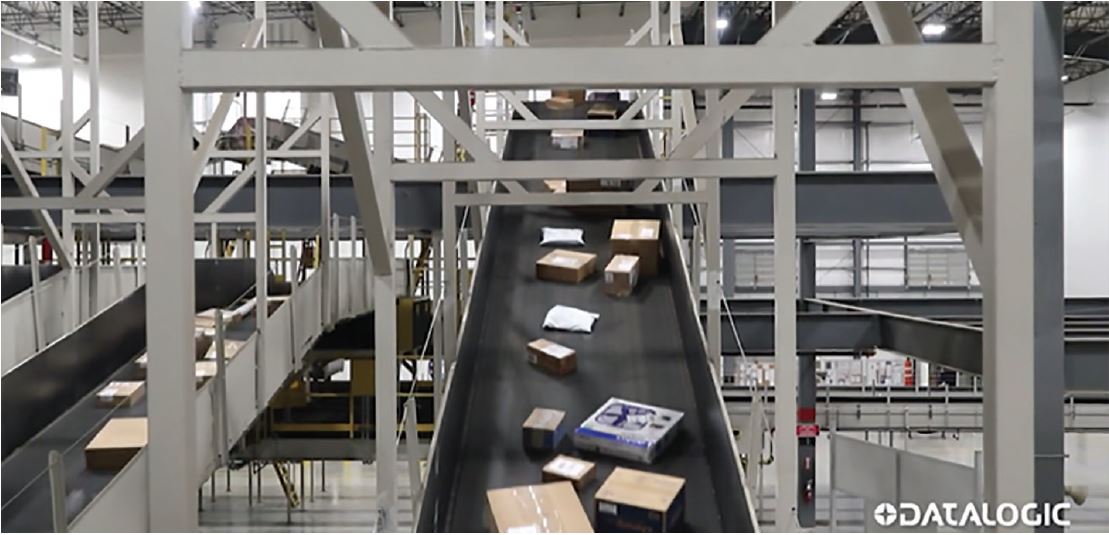

Datalogic, a global technology company specializing in automatic data capture and production of bar code readers, has taken their expertise in barcode readers and developed a “revolutionary industrial scanner” that reads at a rate of 99.9%. This new scanner provides enhancements like a much larger scanning projection, 16:9 to provide maximum resolution.

Pragmatyxs is your trusted partner to implement a product labeling solution and ensure it works seamlessly with your barcode scanning system. Our holistic approach enables you to have a solution that drives efficiency and reduces the resource burden.

Source: Datalogic white paper– New FOV and Pixel Density Improves Traceability Accuracy